John Deere Tractor Belts: The Unsung Heroes of Sustainable Farming

John Deere tractor belts are often overlooked, yet they are crucial components powering essential tractor functions, from the power take-off (PTO) to hydraulic systems. Their reliability directly impacts farming efficiency and sustainability. A malfunctioning belt leads to downtime, impacting harvests and increasing the environmental footprint through unnecessary replacements. How can farmers maximize belt lifespan and minimize their environmental impact? Let's explore the critical role of belt longevity in sustainable farming practices. For more information on specific models, see the John Deere Model D page.

The Long-Term Value of Belt Longevity

Durability translates directly into reduced downtime and long-term cost savings. Fewer breakdowns equate to increased farming productivity and reduced reliance on new belt manufacturing, which consumes resources and energy, ultimately lowering the carbon footprint. This is especially relevant considering the high energy demand of belt production.

Understanding the Total Cost of Ownership (TCO)

Consider the Total Cost of Ownership (TCO) when assessing belt purchases. The initial cost of a high-quality belt is offset by the reduced need for replacements, minimizing labor costs, productivity losses, and environmental impact from disposal. Investing in durable belts represents a sustainable financial and environmental strategy in the long run. Studies have shown that high-quality belts can reduce replacement frequency by up to 40%, leading to significant cost savings.

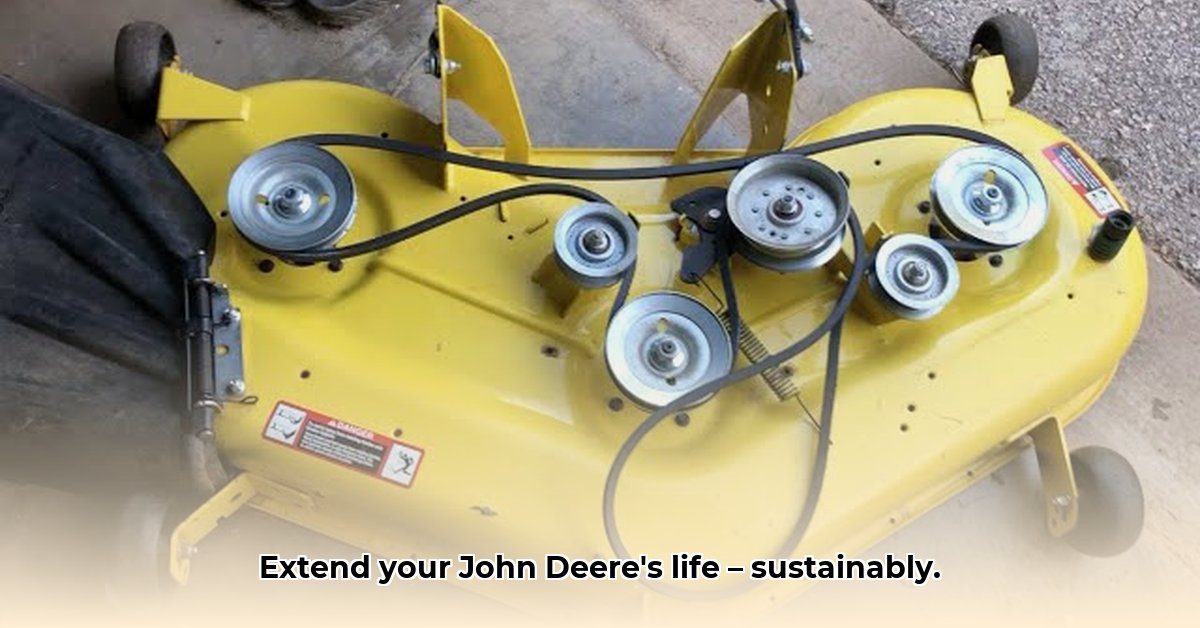

A Practical Guide to Extending Belt Life

Preventative maintenance is key to maximizing belt lifespan and avoiding costly replacements. This simple routine significantly extends the operational life of your belts:

Monthly Visual Inspection: Regularly inspect belts for cracks, fraying, glazing, or other signs of wear. Early detection prevents catastrophic failure.

Tension Check: Ensure proper belt tension according to your tractor’s manual. Incorrect tension leads to premature wear or slippage.

Cleanliness: Regularly clean belts using a brush and compressed air to remove dirt and debris that accelerate wear.

Timely Replacement: Replace worn belts promptly. A seemingly small investment prevents costly repairs and downtime later.

Sustainability Beyond the Belt: A Holistic Approach

While durable belts contribute significantly to sustainable farming, it's crucial to adopt a holistic approach. This includes optimizing fuel efficiency, employing responsible land management practices, and integrating environmentally friendly farming methods. These components together form a unified system of sustainable practices.

Innovations in Sustainable Belt Technology

The agricultural industry is continually innovating to minimize environmental impact. Research focuses on:

- Recycled Materials: Using recycled materials in belt manufacturing reduces reliance on virgin resources.

- Bio-based Polymers: Employing bio-based polymers offers a renewable alternative to traditional materials.

- Closed-Loop Recycling: Implementing closed-loop recycling programs recovers valuable materials from end-of-life belts. These innovative advancements will lead to even greater sustainability in agriculture.

Reducing the Environmental Impact of John Deere Drive Belt Replacements

Replacing a John Deere drive belt, particularly in models like the 325 and X360, is often a complex process. Minimizing the environmental consequences of these replacements requires a multi-pronged approach.

Extending Belt Lifespan: Prevention as a Sustainable Practice

Proactive maintenance is crucial. Regular inspections, accurate tensioning, and cleanliness significantly extend belt life. Maintaining appropriate storage conditions for spare belts further avoids premature degradation.

Choosing the Right Belt: A Sustainable Purchasing Strategy

Selecting the correct replacement belt is paramount. Incorrect sizing accelerates wear and necessitates more frequent replacements. Always verify part numbers using multiple sources before purchasing a new belt.

Responsible Disposal and Recycling: Minimizing Landfill Waste

Even with preventative measures, belts eventually require replacement. The responsible management of discarded belts is crucial for environmental stewardship. Farmers should explore recycling programs accepting rubber products and consider repurposing old belts where possible.

The Role of John Deere Dealers in Sustainable Practices

John Deere dealers play an important role in promoting sustainability. They can improve part number accuracy, stock eco-friendly belts, and educate customers on sustainable practices and responsible disposal. This cooperation is essential for a more sustainable farming future.

Key Takeaways: Implementing preventative maintenance, making smart purchasing decisions, responsibly disposing of old belts, and collaborating with John Deere dealers are essential steps towards a more environmentally friendly and economically sound approach to managing John Deere tractor belts.